John Deere 710 P-Tier Backhoe

Backhoes

How can we help?

(208) 324-2900

Specifications

CAPACITIES - Boom Lift - Maximum Reach - Non-Extending Dipper, kg (lbs): |

2173 (4791) |

CAPACITIES - Bucket Breakout - General Purpose, kN (lbf): |

73.6 (16539) |

CAPACITIES - Bucket Capacity - Standard General Purpose, m³ (yd³): |

1.24 (1.62) |

CAPACITIES - Bucket Tearout - Non-Extending Dipper, kN (lbf): |

78.4 (17622) |

CAPACITIES - Fuel Tank, ltr (gallons (US)): |

174.1 (46) |

CAPACITIES - Hydraulic Tank, ltr (gallons (US)): |

50.1 (13.2) |

CAPACITIES - Lift To Full Height - General Purpose Bucket, kg (lbs): |

4475 (9866) |

CAPACITIES - Pump: |

Variable Axial Piston Pump |

CAPACITIES - Stick tearout, kN (lbf): |

53.4 (11999) |

DIMENSIONS - Bucket Pin Height - General Purpose, mm (ft/in): |

3730 (12 ft 3 in) |

DIMENSIONS - Bucket Rotation - Position 1, Degrees: |

190 |

DIMENSIONS - Digging Depth - General Purpose, mm (inches): |

157 (6.2) |

DIMENSIONS - Dump Height - General Purpose, mm (ft/in): |

2890 (9 ft 6 in) |

DIMENSIONS - Dump Reach - General Purpose, mm (inches): |

768 (30.2) |

DIMENSIONS - Ground Clearance, mm (inches): |

356 (14) |

DIMENSIONS - Height over std Stick, mm (ft/in): |

4230 (13 ft 10 in) |

DIMENSIONS - Max length with std. Stick, mm (ft/in): |

8230 (27 ft ) |

DIMENSIONS - Wheelbase - 4WD, mm (ft/in): |

2550 (8 ft 4 in) |

DIMENSIONS - Width - General Purpose Bucket, mm (ft/in): |

2464 (8 ft 1 in) |

DIMENSIONS - Width over tires, mm (ft/in): |

2370 (7 ft 9 in) |

DRIVELINE - Displacement, ltr (Inches³): |

4.5 (276) |

DRIVELINE - Engine Manufacturer: |

John Deere |

DRIVELINE - Engine Model: |

PowerTech Plus 4045HT084 |

DRIVELINE - Engine Output - Net, kW (hp): |

110 (148) |

DRIVELINE - Rated Speed, rpm: |

2240 |

DRIVELINE - Service Brake Actuation: |

Hydraulic |

DRIVELINE - Service Brake Type: |

Multi Disc |

DRIVELINE - Transmission Type: |

Power Shift |

WEIGHTS - Operating Weight, kg (lbs): |

11698 (25790) |

Easy to Operate Autoshift Transmission

Powershift™ Transmission

Powershift™ Transmission

John Deere continues with its PowerShift™ Transmission and can be manually shifted by use of the transmission control lever. 5 forward, 3 reverse gears.

Autoshift is now included in the base machine configuration. When enabled on the sealed-switch module, Autoshift automatically shifts the PowerShift™ transmission to the appropriate gear. Simply set the control lever to the highest gear desired, and the transmission will optimally shift based on engine rpm and ground speed.

- Heavy duty transmission oil filter standard on all machines for increased reliability

- Hydraulically actuated clutch packs for smooth shifting and reliable performance under all operating conditions and loads

- ‘Manual mode’ provides an easy to reach and use twist grip Transmission Control Lever (TCL)

- Autoshift improves the operator experience during transport or load and carry applications

Transmission Control Lever (TCL)

Transmission Control Lever (TCL)

Engine

4.5L John Deere PowerTech™ Plus Engine with Series Turbochargers

4.5L John Deere PowerTech™ Plus Engine with Series Turbochargers

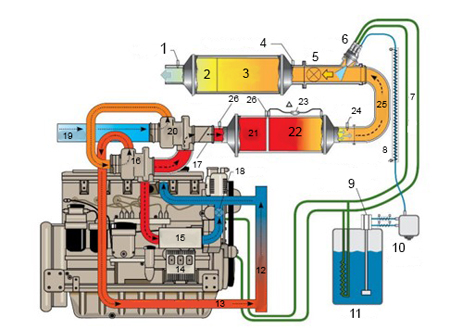

4.5L John Deere PowerTech™ Plus engine rendering

4.5L John Deere PowerTech™ Plus engine rendering

- NO2 sensor

- AOC

- SCR

- Temperature sensor

- Mixer

- DEF injector

- Engine coolant lines

- DEF line

- Header assembly with level and temperature sensor

- DEF supply module and filter

- DEF tank

- Air-to-air cooler

- Compressed air from turbochargers

- ECU

- EGR cooler

- WGT

- Exhaust throttle valve

- EGR valve

- Fresh air

- Fixed

- DOC

- DPF

- Δ P sensor

- NO2 sensor

- Exhaust

- Temperature sensors

Overview

4.5L John Deere PowerTech™ Plus Engine

- For 710 P configurations. EPA Final Tier 4 (FT4)/EU Stage IV emission certified. 148 net peak hp.

- Series Turbocharger design provides great low speed torque

- Aftertreatment design includes:

- Selective catalyst reduction (SCR) system

- Cooled exhaust gas recirculation (EGR)

- Diesel oxidation catalyst (DOC)

- Diesel particulate filter (DPF)

- Diesel exhaust fluid (DEF)

Fold-out front coolers for easy-clean out

Fold-out front coolers for easy-clean out

Electronically Controlled Variable Speed Cooling Fan

Electronically Controlled Variable Speed Cooling Fan

The 710 P uses an electronically controlled variable speed cooling fan. The speed of this fan is controlled by the temperature of various machine systems (engine, hydraulics, transmission, and the like). This means that the fan speed can be reduced when the machine is operating at cooler temperatures. A lower fan speed will reduce horsepower draw from the engine, reduce fuel consumption, and allow a quieter environment for the operator.

Economy Mode

Economy Mode

Economy mode is available through the sealed switch module (SSM). When enabled while facing forward, economy mode sets the engine rpm at a maximum of 2100 rpm in first and second gear. It is limited to 2000 RPM when the seat position is facing the backhoe. This setting can be used in lighter work applications to promote improved fuel efficiency.

Additional factory options

Standard black exhaust extension

Standard black exhaust extension

Optional chrome exhaust extension

Optional chrome exhaust extension

Exceptional hydraulic performance, control, and multifunctioning

Backhoe Hydraulic System

Backhoe Hydraulic System

Pressure-compensated, load sensing (PCLS) hydraulics, provide better multifunctioning, smoother machine control, and up to 15 percent greater craning capacity with Lift Mode, collectively providing a distinctive customer experience and unmatched machine reliability. PCLS are highly valuable for Underground customers due to its productivity, lift capacity, quality and reliability

- The variable displacement axial piston pump creates hydraulic flow on demand, increasing hydraulic efficiency, decreasing fuel consumption, and lowering the daily operating cost for your customer. The field proven SCX 180 rear valve is common for all PCLS machines (320 P, 410 P, 710 P)

- Selective flow auxiliary rate selection adjusted within the main display, eliminating the need to get out of the cab and adjust a manual knob on all PCLS machines.

- Buttons for the horn, selective flow, auxiliary proportional roller, and extendable dipperstick have been incorporated into the pilot controls

- The PCLS system enables excellent multifunctioning ability at all engine speeds.

- Trenching operation can be conducted at a lower engine rpm, reducing fuel consumption and jobsite noise.

- Precision mode reduces hydraulic flow by 55 percent, allowing accurate, detailed backhoe work to be performed without sacrificing overall hydraulic-lift performance. Ideal for working in tight areas, around utilities, or while craning. Inexperienced operators will be able to use this feature to become comfortable with the backhoe, as they master their operating skills. Precision Mode can be activated with the press of a button on the SSM.

Ability to Work in Wet and Muddy Conditions

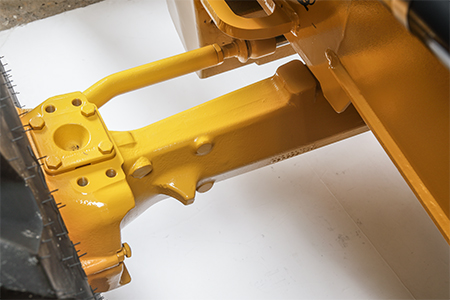

Mechanical Front Wheel Drive (MFWD) Front Axle

Mechanical Front Wheel Drive (MFWD) Front Axle

Mechanical Front Wheel Drive (MFWD) with limited slip differential. The main MFWD on/off control is mounted on the RH console.

- Limited slip front axle delivers 65% of available power to the tire with the best traction for true all-wheel-drive pulling power

- Completely sealed axle has no breathers to maintain or service, promoting reliability (axle breathers can be susceptible to water and/or dirt intrusion)

- The machine will automatically disable the MFWD in 4th gear to reduce tire wear.

- Extend tire tread life with Momentary MFWD for ‘on the fly’ activation. Controlled with a touch of a button on the loader lever. Great for engaging a pile or briefly powering through sticky or slippery terrain.

Transmission Control Lever (TCL)